- who we are

- Quality

- products

- Services

- Contact us

- Assistance

Grinders

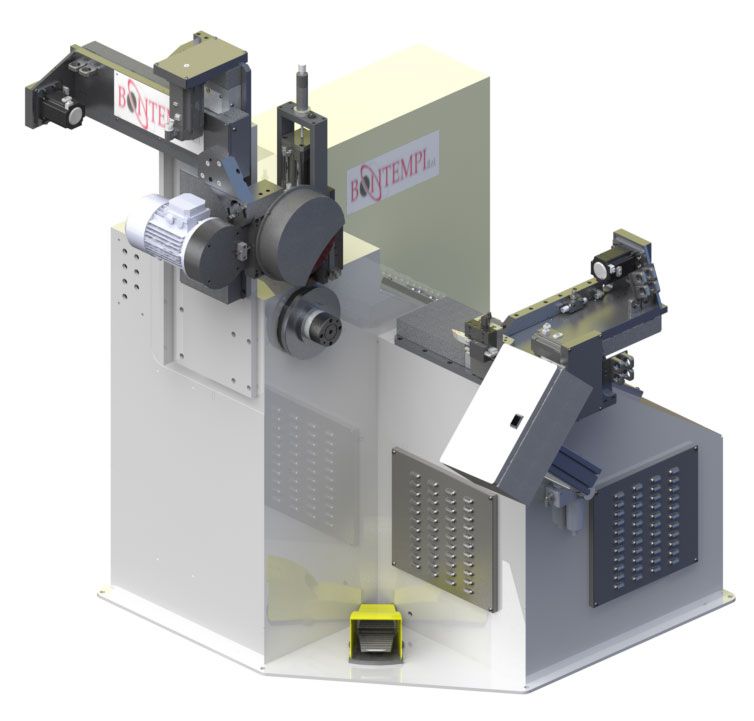

HORIZONTAL AXIS ELECTRONIC LATHE MACHINE WITH GRINDING FOR ALUMINUM TYPE TBE-S

Horizontal axis electronic lathe machine with two carriages to trim aluminum products and a carriage to grind the external surface of the product. The finishing of the bottom is performed by an electronic cross carriage, equipped with brushless motors with interpolated axis and with the possibility of storing up to 500 working procedures; the edge is finished by means of a pneumatic turret. The grinding of the external surface is performed by an electronic cross carriage, equipped with brushless motors with interpolated axis and with the possibility of storing up to 500 working procedures, on which a grinding wheel is mounted, moved by an asynchronous motor. The loading and unloading of the pieces is carried out by the operator. The grinding of the external surface allows to obtain a “professional” finish. Possibility of completing the supply with a dry dust extractor, for effective removal of the wheel scrap from the working area.

Dimensions (width x depth x height) | 1280 x 1660 x 2030 mm |

Weight | 1000 Kg |

Power installed | 10,5 Kw |

Pneumatic consumption | 21,65 Nl/ciclo |

Minimum pan diameter | 120 mm |

Maximum pan diameter | 320 mm |

Minimum pan height | 35 mm |

Maximum pan height | 200 mm |

Motor type | Brushless |

Grinding motor | Asincrono |

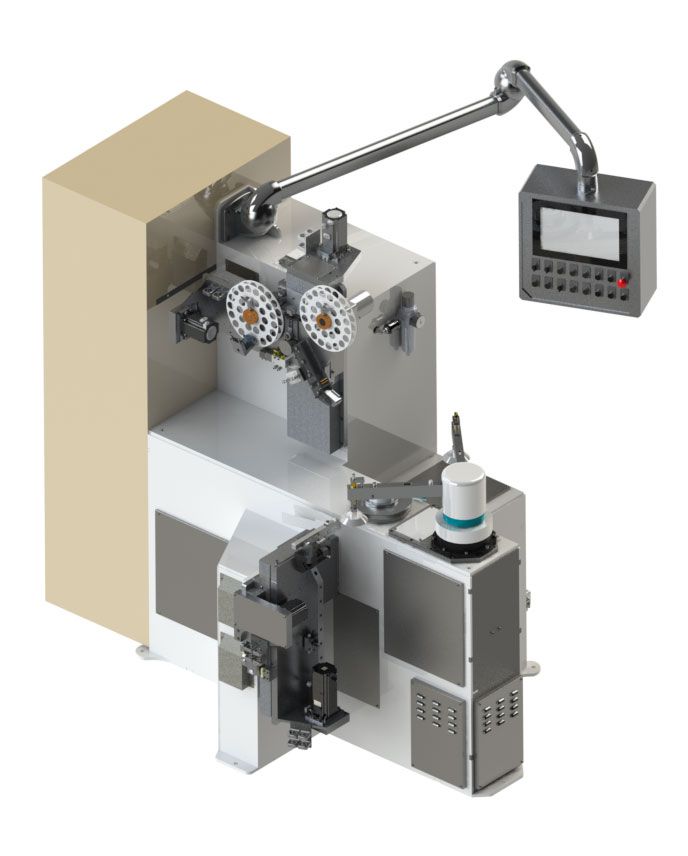

GRINDING MACHINE WITH INTEGRATED LOADING AND UNLOADING SYSTEM TYPE TVCMES

Electronic grinding machine with vertical axis equipped with a carriage and an automatic loading and unloading device to grind the bottom of cookware products (especially aluminium cookware for induction). The grinding of the bottom is performed by a cross carriage equipped with brushless motors with interpolated axis, on which a grinding belt is mounted, moved by an asynchronous motor. Thanks to the automatic loading and unloading device, the grinding machine has a high production capacity. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the parameters related to carriage, loader and spindle are saved. Automatic lubrication system for the carriages and the loading device. Possibility of completing the supply with a lateral carriage, which allows to trim the edge simultaneously with the grinding of the bottom, and with a dry dust extractor, for effective removal of the belt scrap from the working area.

Dimensions (width x depth x height) | 1230 x 2100 x 2800 mm |

Weight | 1600 Kg |

Power installed | 15 Kw |

Pneumatic consumption | 76,5 Nl/ciclo |

Minimum pan diameter | 120 mm |

Maximum pan diameter | 320 mm |

Minimum pan height | 35 mm |

Maximum pan height | 200 mm |

Motor type | Brushless |

Grinding motor | Asincrono |

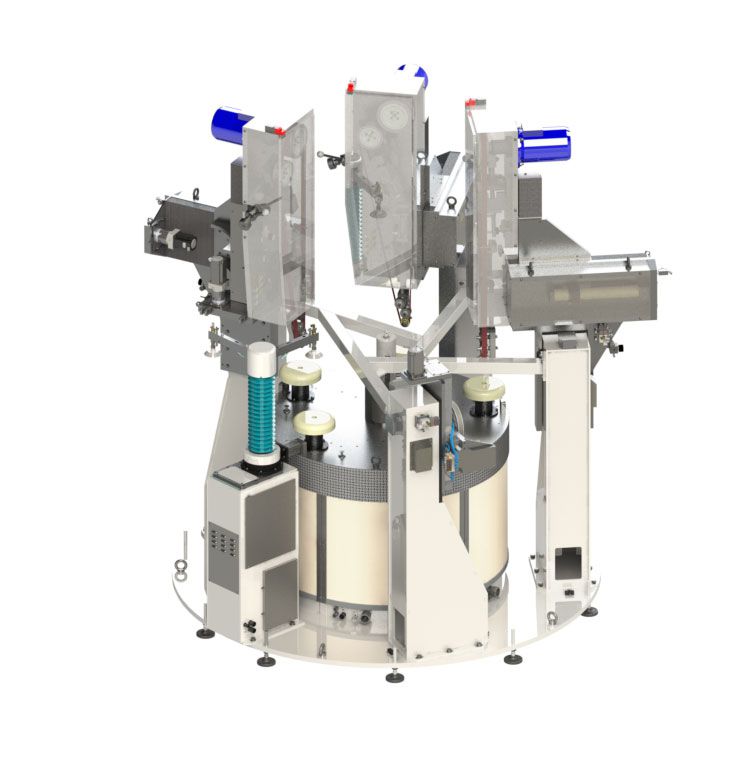

SATIN FINISH MACHINE WITH INTEGRATED LOADING AND UNLOADING SYSTEM TYPE TVPT

Electronic satin machine with vertical axis equipped with two carriages and an automatic loading and unloading device to satin the external surface of cookware products, in order to obtain a “professional” finish. The satin finish of the bottom and the trimming of the edge are performed by two cross carriages equipped with brushless motors with interpolated axis. A scotch brite belt is mounted on the satin finishing carriage, which remains stationary during the cycle, rotating only at the end of cycle to obtain the best possible finish at each cycle. Thanks to the automatic loading and unloading device, the satin machine has a high production capacity. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the parameters related to carriages, loader and spindle are saved. Automatic lubrication system for the carriages and the loading device. Possibility of completing the supply with a dry dust extractor, for effective removal of the belt scrap from the working area.

Dimensions (width x depth x height) | 1420 x 2100 x 1950 mm |

Weight | 1600 Kg |

Power installed | 13,5 Kw |

Pneumatic consumption | 76,5 Nl/ciclo |

Minimum pan diameter | 120 mm |

Maximum pan diameter | 320 mm |

Minimum pan height | 35 mm |

Maximum pan height | 200 mm |

Motor type | Brushless |

5-STATION GRINDING MACHINE TYPE SM5P

Five-station grinding machine, with rotating board to allow the translation of the pieces. Ideal to grind the bottom of cookware products (especially aluminum cookware for induction). In the first station, an electronic loading and unloading arm automatically removes the finished piece from the last unit, and simultaneously loads a piece from a conveyor belt; from the second to the fourth station, three grinding units perform the grinding of the bottom of the products, and in the fifth station a satin finishing unit carries out the finishing of the product. Thanks to the loading and unloading device and to the presence of multiple grinding stations, the machinery has a high hourly production capacity. The grinding of the bottom is performed by three cross carriages equipped with brushless motors with interpolated axis, on which a grinding belt is mounted, moved by an asynchronous motor. The scotch brite satin unit is also mounted on a cross carriage equipped with brushless motors with interpolated axis. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the parameters related to carriages, loader, spindle and board motors are saved. Possibility of completing the supply with a dry dust extractor, for effective removal of the belt scrap from the work area.

Dimensions (width x depth x height) | 3900 x 4400 x 3000 mm |

Power installed | 34 Kw |

Pneumatic consumption | 119 Nl/ciclo |

Minimum pan diameter | 120 mm |

Maximum pan diameter | 320 mm |

Minimum pan height | 35 mm |

Maximum pan height | 200 mm |

Motor type | Brushless |

Grinding motor | Asincroni |

© 2020 BONTEMPI SRL - VIA CAPORALINO 1/I

25060 - Cellatica (BS)

P.IVA C.F. 03414090179 - REA 393141 -

CAP.SOC. € 30.000 i.v.

Tel. +39 030 252 2999 - Fax. +39 030 277 0644 - Email: This email address is being protected from spambots. You need JavaScript enabled to view it.