- who we are

- Quality

- products

- Services

- Contact us

- Assistance

aluminum welding machines

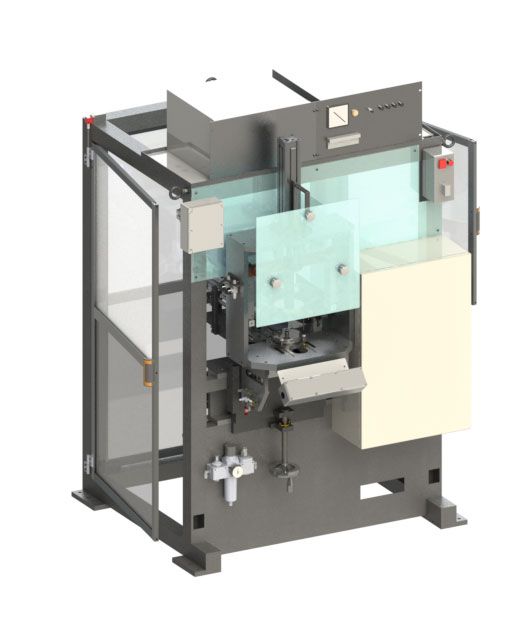

ONE STATION WELDING MACHINE TYPE SW1

Capacitive discharge welding unit, single station. The loading of the product and the goujon to be welded are carried out by the operator. Welding can only be made on the unpainted product. Ideal machinery for small hourly productions.

2 STATIONS WELDING MACHINE TYPE SW2/BE

Capacitive discharge welding unit, two stations. The operator manually loads and unloads the piece, while the machine removes the paint and welds the aluminum goujon, which is automatically loaded by means of a goujon carriage connected to a vibrating cup for the selection of the goujon. When the operator loads the piece, the milling cutter removes the paint, the mold rotates of 180° and the welding head proceeds to weld the goujon. Possibility of welding the double goujon, always using the rotation of the mold on which the piece to be welded is positioned.

Dimensions (width x depth x height) | 1500 x 1070 x 1900 mm |

Weight | 630 Kg |

Power installed | 2,5 Kw |

Pneumatic consumption | 16,2 Nl/ciclo |

2 STATIONS WELDING MACHINE WITH TEST TYPE SW2/2T

Capacitive discharge welding unit, two stations. The operator manually loads and unloads the piece, while the machine removes the paint, welds the aluminum goujon, which is automatically loaded by means of a goujon carriage connected to a vibrating cup for the selection of the goujon, and tests the goujon. When the operator loads the piece, the milling cutter removes the paint, the units translate and the welding head proceeds to weld and then to test the goujon, by means of rotation of the front part of the special welding head. Possibility of welding the double goujon, using the rotation of the mold on which the piece to be welded is positioned.

Dimensions (width x depth x height) | 1140 x 1350 x 1900 mm |

Weight | 650 Kg |

Power installed | 2,5 Kw |

Pneumatic consumption | 16,2 Nl/ciclo |

4 STATION WELDING MACHINE WITH MANUAL LOAD TYPE SW4/2

Four-station welding machine, with rotating board to allow the translation of the pieces. In the first station the operator loads the piece, in the second station the cutter removes the paint, in the third station the welding head proceeds to weld the goujon, in the fourth station a testing unit proceeds to test the goujon and the operator manually unloads the piece. The standard machinery is provided with adjustable handwheels to adjust all the positions of the units; possibility of making the machinery self-dimensioning, through the use of linear actuators that allow to store all the positions according to the type of product to be welded. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the positions of the units are saved. Possibility of welding the double goujon, using the rotation of the molds on which the pieces to be welded are positioned.

Dimensions (width x depth x height) | 1650 x 1830 x 2065 mm |

Weight | 1400 Kg |

Power installed | 2,5 Kw |

Pneumatic consumption | 38,5 Nl/ciclo |

Minimum pan diameter | 140 mm |

Maximum pan diameter | 360 mm |

Minimum pan height | 25 mm |

Maximum pan height | 200 mm |

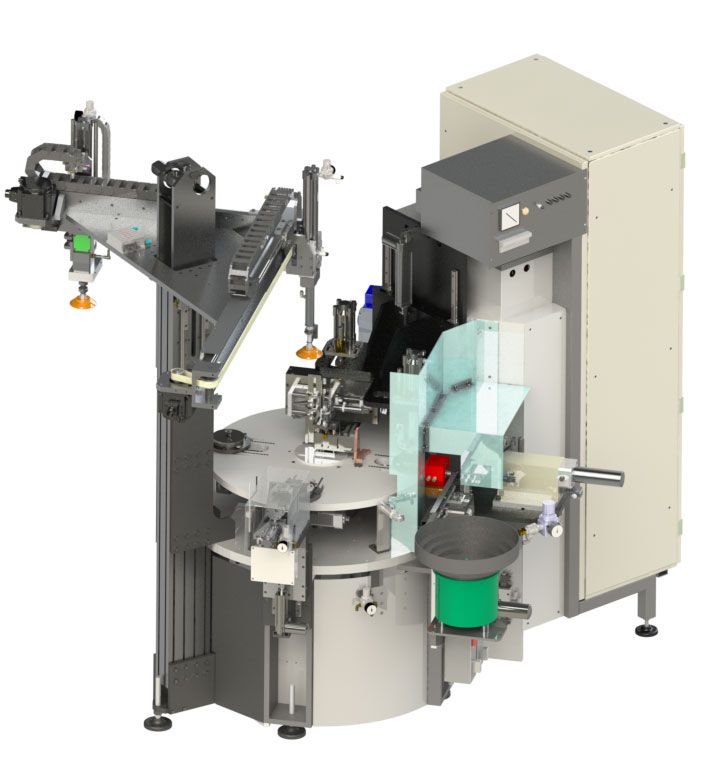

4-STATION WELDING MACHINE WITH AUTOMATIC LOADING AND UNLOADING SYSTEM TYPE SW4/2-AUTO

Four-station welding machine, with rotating board to allow the translation of the pieces. In the first station an electronic loading arm automatically loads the piece coming from a conveyor belt, in the second station the cutter removes the paint, in the third station the welding head proceeds to weld the goujon, in the fourth station a testing unit proceeds to test the goujon and an electronic unloading arm automatically unloads the piece, placing it on a conveyor belt or a roller conveyor. Thanks to the automatic loading and unloading device, the machinery has a high production capacity and is usually integrated within a high productivity line. The standard machinery is provided with adjustable handwheels to adjust all the positions of the units; possibility of making the machinery self-dimensioning, through the use of linear actuators that allow to store all the positions according to the type of product to be welded. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the positions of the units are saved. Possibility of welding the double goujon, using the rotation of the molds on which the pieces to be welded are positioned. Possibility of integrating a vision system for the orientation of the logo with respect to the goujon to be welded.

Dimensions (width x depth x height) | 2300 x 2800 x 2270 mm |

Weight | 1670 Kg |

Power installed | 5 Kw |

Pneumatic consumption | 48,2 Nl/ciclo |

Minimum pan diameter | 140 mm |

Maximum pan diameter | 360 mm |

Minimum pan height | 25 mm |

Maximum pan height | 200 mm |

6-STATION WELDING MACHINE WITH AUTOMATIC LOADING AND UNLOADING SYSTEM TYPE SW6/2

Six-station welding machine, with rotating board to allow the translation of the pieces. In the first station an electronic loading arm automatically loads the piece coming from a conveyor belt, in the second station the cutter removes the paint, in the third station the welding head proceeds to weld the goujon, in the fourth station a testing unit proceeds to test the goujon, in the fifth station a semiautomatic screwdriver proceeds to screw the handle, which must be positioned manually by the operator in its seat, in the sixth station an electronic unloading arm automatically unloads the piece, placing it on a tilter or on a conveyor belt. Thanks to the automatic loading and unloading device, the machinery has a high production capacity and is usually integrated within a high productivity line. The standard machinery is provided with adjustable handwheels to adjust all the positions of the units; possibility of making the machinery self-dimensioning, through the use of linear actuators that allow to store all the positions according to the type of product to be welded. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the positions of the units are saved. Possibility of welding the double goujon, using the rotation of the molds on which the pieces to be welded are positioned. Possibility of integrating a vision system for the orientation of the logo with respect to the goujon to be welded.

Dimensions (width x depth x height) | 3300 x 3300 x 2300 mm |

Weight | 2950 Kg |

Power installed | 5 Kw |

Pneumatic consumption | 59 Nl/ciclo |

Minimum pan diameter | 140 mm |

Maximum pan diameter | 360 mm |

Minimum pan height | 25 mm |

Maximum pan height | 200 mm |

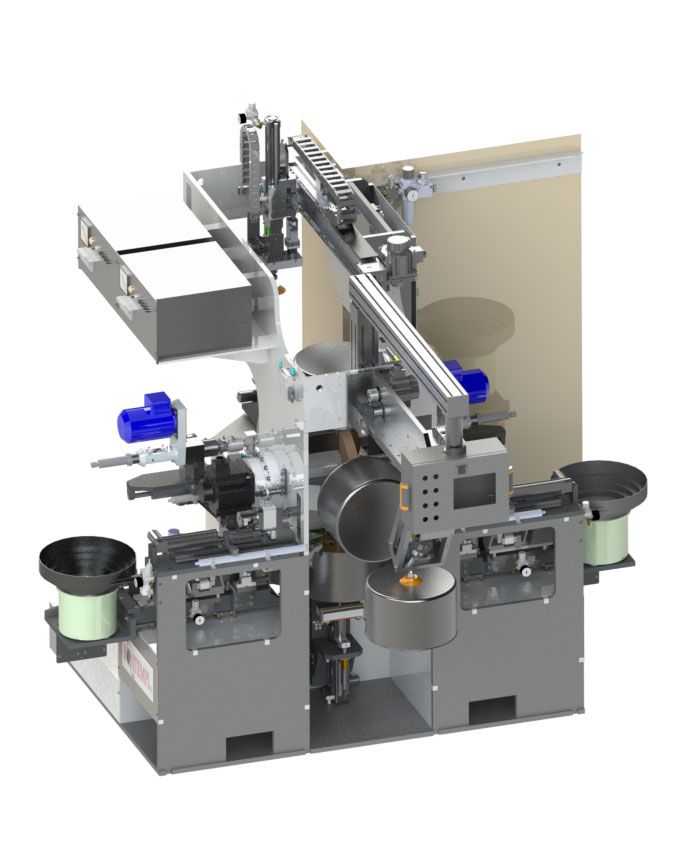

4-STATION VERTICAL WELDING MACHINE TYPE SW4/V

Four-station welding machine, with vertical rotating board to allow the translation of the pieces. The molds are positioned tangentially to the rotation axis of the board. It is equipped with double units for each type of processing to be performed (milling, welding and testing). In the first station, positioned upwards, an electronic loading arm automatically loads the piece coming from a conveyor belt, in the second station the cutters remove the paint, in the third station the welding heads proceed to weld the goujons, in the fourth station, the testing units proceed to test the goujons and an electronic unloading arm automatically unloads the piece, placing it on a conveyor belt. Thanks to the automatic loading and unloading device and the double units, the machinery allows high productivity both for products with single goujon and for products with double goujon, and is usually integrated within a high productivity line. The standard machinery is self-dimensioning, through the use of linear actuators that allow to store all the positions according to the type of product to be welded. The whole machine is managed from a touch-screen panel, with the option of storing up to 500 working procedures, in which all the positions of the units are saved. Possibility of integrating a vision system for the orientation of the logo with respect to the goujon to be welded.

Dimensions (width x depth x height) | 2540 x 2600 x 2260 mm |

Weight | 2630 Kg |

Power installed | 13 Kw |

Pneumatic consumption | 37,6 Nl/ciclo |

Minimum pan diameter | 140 mm |

Maximum pan diameter | 360 mm |

Minimum pan height | 25 mm |

Maximum pan height | 200 mm |

© 2020 BONTEMPI SRL - VIA CAPORALINO 1/I

25060 - Cellatica (BS)

P.IVA C.F. 03414090179 - REA 393141 -

CAP.SOC. € 30.000 i.v.

Tel. +39 030 252 2999 - Fax. +39 030 277 0644 - Email: This email address is being protected from spambots. You need JavaScript enabled to view it.